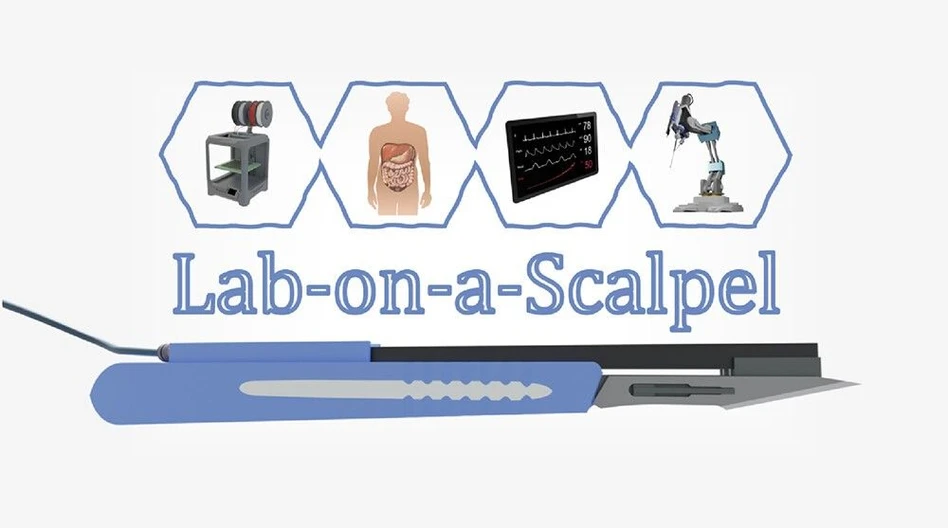

Lab-on-a-Scalpel: Medical Tool Incorporating a Disposable Fully 3D-Printed Electrochemical Cell Promoting Drop-Volume Chemical Analysis in the Operating Theater

Anal. Chem. 2025, 97, 20, 10709–10719: Graphical abstract

Surgical procedures demand real-time biochemical monitoring to ensure patient safety. To address this need, researchers designed a fully 3D-printed, disposable electrochemical cell integrated into a surgical scalpel — termed “Lab-on-a-Scalpel.” This innovative device enables rapid, near-patient chemical analysis in the operating theater, reducing the number of required instruments and production costs.

The Lab-on-a-Scalpel demonstrated strong analytical performance in epinephrine detection using cyclic voltammetry, amperometry, and differential pulse voltammetry. With a detection limit of 0.13 μM and high accuracy in artificial blood samples, this tool shows great potential for real-time, drop-volume biochemical testing and future integration into robotic-assisted surgery.

The original article

Lab-on-a-Scalpel: Medical Tool Incorporating a Disposable Fully 3D-Printed Electrochemical Cell Promoting Drop-Volume Chemical Analysis in the Operating Theater

Anastasios V. Papavasileiou*, Lukáš Děkanovský, and Zdeněk Sofer*

Anal. Chem. 2025, 97, 20, 10709–10719

https://doi.org/10.1021/acs.analchem.5c00599

licensed under CC-BY 4.0

Selected sections from the article follow. Formats and hyperlinks were adapted from the original.

Surgical operations are critical and complex procedures due to their invasive nature that disrupts the physiological functions of the human body. The inherent risks associated with such operations include bleeding, infection, damage to surrounding tissues or organs, and adverse effects on medication or implants. These issues can compromise postsurgical recovery, biological functions, or even the survival of the patients. Therefore, the continuous monitoring of their conditions is imperative in order to identify abnormalities and risks and make early interventions. (1−3) Beyond the typical vital signs that need to be tracked during surgery (heart rate, blood pressure, respiratory rate, temperature, oxygen level, blood loss, fluid levels, etc.), the abrupt concentration change of biomarkers, metabolites, and stress hormones in the biological fluids of a patient is also indicative of surgical complications and abnormalities. (4−6)

The requirements of instantaneous and on-site chemical analysis in operating rooms cannot be met by the current methods of chemical analysis (such as chromatographic (7) and spectroscopic techniques (8)) due to high instrumentation and operation costs, lack of portability, and the demand of qualified personnel to obtain reliable results. In recent years, mobile testing and rapid diagnostics through Point-of-Care (PoC) technologies have attracted notable interest from the scientific community and medical professionals. A PoC-compatible method relies on affordable, portable, and user-friendly devices that enable reliable and rapid diagnostics outside of a laboratory setting. (9,10) Employing PoC methods in the operating theater during a surgical procedure provides real-time patient diagnostics by eliminating the need for formal requests of sample analysis to the hospital’s biochemical laboratories. The long waiting times behind test ordering and receiving lab reports can be significantly decreased. This way the clinician can coordinate care by making faster and more informed decisions and engage in improved treatment plans that lead to an overall better patient postsurgical recovery. (11,12)

Electrochemical sensors possess multiple benefits (portability, affordability, easy miniaturization, high sensitivity, etc.) that render them attractive options for on-site chemical analysis and, thus, PoC diagnostic devices. (13) The integration of carbon allotropes (graphene, carbon black, and more) in thermoplastic materials unlocked the use of 3D printing technology for the on-demand fabrication of low-cost and sustainable electrochemical sensors. This approach enables the fabrication of advanced electrochemical sensing devices without any design constraints. (14) The desktop size and affordability of a 3D printer in combination with the fast and easy fabrication process render fused deposition modeling (FDM) an ideal method for electrochemical sensor production. (15)

So far, several studies have utilized FDM 3D printing for the fabrication of electrodes, (15) cells, (16−18) and devices (19,20) for analytical purposes. Even though most of these sensors offer promising analytical features, there are some considerations that need to be addressed to be suitable for near-patient monitoring during surgical operations: (i) to minimize the demand for large sample volumes, which are limited and scarce during a surgical procedure, (ii) to provide a compact sensing platform that will integrate all the necessary components without the need of assembling, and (iii) to be cost-effective for single-use to avoid cross-contamination in a sterile environment such as the operating room.

Herein, we present the fabrication of a disposable and compact fully 3D-printed electrochemical cell incorporated into a medical scalpel, enabling near-patient monitoring of surgical operations through a drop-volume voltammetric analysis, introducing the concept of the Lab-on-a-Scalpel (Scheme 1).

Anal. Chem. 2025, 97, 20, 10709-10719: Scheme 1. Graphical Illustration of the Lab-on-a-Scalpel Device with the Sensor and the Blade Attached (Top); Side, Front, and Top Views of the Fully 3D-printed Triple Electrode, along with Its Geometrical Characteristics (Bottom Left); and Real Photo of the Lab-on-a-Scalpel Sensing Device (Bottom Right)

Anal. Chem. 2025, 97, 20, 10709-10719: Scheme 1. Graphical Illustration of the Lab-on-a-Scalpel Device with the Sensor and the Blade Attached (Top); Side, Front, and Top Views of the Fully 3D-printed Triple Electrode, along with Its Geometrical Characteristics (Bottom Left); and Real Photo of the Lab-on-a-Scalpel Sensing Device (Bottom Right)

Representing a new approach, the Lab-on-a-Scalpel serves as a reliable, fast, and facile sensing platform that can be produced on-demand with a desktop-sized 3D printer at a very low cost (0.40 € per sensor). The combination of an essential surgical tool with an electrochemical sensor results in a multifunctional tool, which limits the number of instruments needed in the operating room. Additionally, it aims to minimize the delays during critical moments in surgery by offering real-time monitoring of the patient’s biochemical profile, contributing to an overall better patient care.

The sensor was investigated for the determination of epinephrine, which is also known as adrenaline. This hormone is crucial as it can be released in humans during stress, while it has also been used by medical professionals to control bleeding, prolong anesthesia, and tackle emergency medical situations such as anaphylaxis or cardiac events. (21,22) The electrochemical determination of epinephrine using this sensor was explored under different techniques such as cyclic voltammetry (CV), differential pulse voltammetry (DPV), and amperometry, and diverse experimental conditions (drop-volume analysis, polarization potential, stirring, etc.), aiming to fully explore its sensing capabilities across different modes of analysis. The reliability and accuracy of the sensing device were assessed separately for each of the proposed methods of analysis through recovery studies in artificial blood samples.

Materials and Methods

Structural Characterization

Raman spectra were measured using an inVia Raman spectroscope (Renishaw, UK) in backscattering geometry equipped with a charge-coupled device detector using a DPSS green laser (532 nm, 50 mW), with an applied power of 5 mW and a 20× magnification objective.

Electrochemical Measurements

Electrochemical measurements were conducted using a Corrtest 4-channel potentiostat at room temperature. Electrochemical characterization was carried out with the electrochemically activated CB/PLA 3D-printed electrode serving as the working electrode, Pt foil serving as the counter electrode, and a Ag/AgCl, 3 M KCl electrode acting as the reference electrode. Electrochemical measurements for the determination of epinephrine were performed with the fully 3D-printed electrochemical cell consisting of electrochemically activated CB/PLA 3D-printed electrodes serving as counter and pseudoreference electrodes, depicted in Scheme 1.

Electrochemical impedance spectroscopy (EIS) was carried out in a frequency range from 100 kHz to 0.1 Hz, with an amplitude of the applied AC potential of 5 mV, superimposed on a DC potential of 0.2 V. Cyclic voltammograms (CV) were recorded in 0.1 M PBS pH 6 at 25 mV s–1 unless stated otherwise. Differential pulse (DP) voltammograms of epinephrine were recorded in 0.1 M PBS pH 6 in a potential range between −0.2 and 0.6 V using the following waveform parameters: 0.004 V, amplitude: 0.05 V, modulation time: 0.05 s. Under these conditions, the effective scan rate was 0.008 V s–1. Amperometric measurements were conducted in stirred (200 rpm) 0.1 M PBS pH 6 at a polarization potential of +0.5 V, unless stated otherwise.

Results and Discussion

Electrochemical Characterization

The electrochemical behavior of the working electrode was evaluated by monitoring the electron transfer properties of a standard redox system using a conventional three-electrode system (Ag/AgCl as the reference and Pt foil as the counter). For this purpose, 1 mM hexacyanoferrate (III) in 0.1 M PBS pH 7 through CV was carried out at a scan rate of 50 mV s–1. Under the same experimental conditions, the suitability of CB/PLA-based counter and pseudoreference (31) electrode was investigated. The voltammetric profile of the fully 3D-printed electrochemical cell demonstrated in Figure 1 illustrates an identical shape and peak current with the conventional electrochemical cell, shifted by ca. 0.33 V toward negative potential values.

Anal. Chem. 2025, 97, 20, 10709–10719: Figure 1. Cyclic voltammograms of CB/PLA 3D-printed electrodes in the presence of 1 mM hexacyanoferrate (III) at a scan rate of 50 mV s–1 using a conventional electrochemical cell where Pt foil serves as counter electrode and Ag/AgCl as reference electrode (black); CVs obtained using the fully printed electrochemical cell consisting of a CB/PLA counter electrode and pseudoreference electrode (red).

Anal. Chem. 2025, 97, 20, 10709–10719: Figure 1. Cyclic voltammograms of CB/PLA 3D-printed electrodes in the presence of 1 mM hexacyanoferrate (III) at a scan rate of 50 mV s–1 using a conventional electrochemical cell where Pt foil serves as counter electrode and Ag/AgCl as reference electrode (black); CVs obtained using the fully printed electrochemical cell consisting of a CB/PLA counter electrode and pseudoreference electrode (red).

Additionally, Figure S4 demonstrates the performance of five similarly prepared fully 3D-printed electrochemical cells. The stable peak current response (RSD = 6.15%) ascertains the reproducible behavior of the working electrode, while the constant half-wave potential E1/2 (RSD = 4.87%) confirms the suitability of the CB/PLA electrode to act as a pseudoreference electrode.

These findings suggest that the fabrication of the fully 3D-printed electrochemical cells is a highly reproducible procedure that yields identical sensing devices that can be used autonomously without the need for any external components (i.e., counter and reference electrode). Henceforth, the fully 3D-printed electrochemical cell is utilized in further investigations.

Epinephrine Electrooxidation

The sensing capabilities of the fully 3D-printed electrochemical cell were explored with the use of epinephrine as a model analyte. It is undoubtedly one of the most important hormones to track during a surgical operation, as its abrupt concentration fluctuations are indicative of excessive stress in the body functions. Additionally, in many cases, epinephrine is injected into the patient during a surgical operation to minimize bleeding and improve the depth and duration of anesthesia. The lowest effective dose of epinephrine can improve the results of the surgery. (22) Considering that the accurate and instantaneous determination of epinephrine in the course of a surgical operation is of paramount importance.

Previous studies have shown that epinephrine sensing is favorable in slightly acidic conditions. (32,33) Data demonstrated in Figure S5 come in accordance with those studies, showing that epinephrine electrooxidation is pH-dependent, and its determination is facilitated at pH 6. Hence, all the subsequent experiments in this research work took place at a pH of 6.

Τhe electrochemical determination of epinephrine relies on its oxidation to the quinone derivative. The mechanism of that reaction was revisited by Bacil et al., who proved that it follows a multistep electron transfer with a swift intramolecular cyclization. (34) Their findings suggest that the reaction is pH-dependent and highlight that at pH values higher than 5.21 (pKa), the deprotonated epinephrine can undergo a cyclization after electrochemical oxidation to the quinone derivative. Later on, the cyclic quinone derivative can be electrochemically reduced to form cyclic epinephrine (Figure 2A).

Anal. Chem. 2025, 97, 20, 10709–10719: Figure 2. (A) Graphical illustration of epinephrine oxidation reaction following the “C”EECEE mechanism as proposed from Bacil et al. (34) and (B) Cyclic voltammograms measured with fully 3D-printed electrochemical cell in 0.1 M PBS pH 6 containing 10 μM epinephrine, at scan rates ranging from 10 to 400 mV s–1, along with the plot of peak current vs the scan rate and the square root of scan rate with the respective regression equations.

Anal. Chem. 2025, 97, 20, 10709–10719: Figure 2. (A) Graphical illustration of epinephrine oxidation reaction following the “C”EECEE mechanism as proposed from Bacil et al. (34) and (B) Cyclic voltammograms measured with fully 3D-printed electrochemical cell in 0.1 M PBS pH 6 containing 10 μM epinephrine, at scan rates ranging from 10 to 400 mV s–1, along with the plot of peak current vs the scan rate and the square root of scan rate with the respective regression equations.

Modes of Determination

The performance of the fully 3D-printed triple electrode for the determination of epinephrine was investigated under different experimental setups by using various electrochemical techniques. Figure 3A–C illustrates the experimental setup corresponding to the techniques: (A) stationary voltammetric mode, (B) hydrodynamic amperometric mode, and (C) differential pulse voltammetry. The figure also highlights key experimental parameters such as whether stirring was applied and/or the volume of the working solution during the analysis. Voltammetric analysis was carried out in 0.1 M PBS (pH 6) in the presence of varying concentrations of epinephrine, and the results are demonstrated in Figure 3A′–C′ along with the corresponding calibration plots (Figure 3A″–C″).

Anal. Chem. 2025, 97, 20, 10709–10719: Figure 3. Modes of determination of epinephrine with fully 3D-printed electrochemical cell. (A–C) Graphical illustration of the experimental setup of the measurement, (A′, Α″) CVs in the range from 0.5 to 435 μM of epinephrine at a scan rate of 25 mV s–1 and the respective calibration plot, (Β′, B″) amperometric curve at a polarization potential of +0.5 V in a stirred (200 rpm) 0.1 M PBS (pH 6) in the range from 1.0 to 215 μM of epinephrine and the respective calibration plots, and (C′, C″) DP voltammograms of drop-volume analysis in the range from 0.5 to 20 μM of epinephrine and the respective calibration plots.

Anal. Chem. 2025, 97, 20, 10709–10719: Figure 3. Modes of determination of epinephrine with fully 3D-printed electrochemical cell. (A–C) Graphical illustration of the experimental setup of the measurement, (A′, Α″) CVs in the range from 0.5 to 435 μM of epinephrine at a scan rate of 25 mV s–1 and the respective calibration plot, (Β′, B″) amperometric curve at a polarization potential of +0.5 V in a stirred (200 rpm) 0.1 M PBS (pH 6) in the range from 1.0 to 215 μM of epinephrine and the respective calibration plots, and (C′, C″) DP voltammograms of drop-volume analysis in the range from 0.5 to 20 μM of epinephrine and the respective calibration plots.

Conclusions

In this work, we successfully developed a novel, compact, and disposable fully 3D-printed electrochemical cell incorporated into the rear side of a medical scalpel, named Lab-on-a-Scalpel. It is a multifunctional tool aiming to promote the intraoperative biochemical monitoring of patients through chemical analysis while minimizing the number of instruments required during surgery. The scalability and on-demand fabrication of the sensor along with the very low cost (0.40 € per sensor) render it a viable and practical alternative to conventional analytical methods. This device holds promise to enhance the efficiency and safety of surgical procedures through immediate near-patient diagnostics. Hence, this approach allows healthcare professionals to make timely and more informed decisions and handle more effectively any detected abnormalities.

Lab-on-a-Scalpel was successfully applied in the electroanalytical determination of epinephrine through different electrochemical techniques, showing competitive analytical figures-of-merit without the need for any modification. The high sensitivity (LOD of 130 nM), the outstanding stability (0.91% RSD of repeatability), and the exceptional accuracy (recovery of 91–105%) render Lab-on-a-Scalpel a promising and reliable sensing device, which shows potential for the implementation across a wide range of biochemical analytes. Moreover, its ability to conduct full chemical analysis with just a 50 μL drop is of high importance during a surgical procedure due to the limited availability of the sample.

Even though the development of this sensing device represents a significant step toward chemical analysis in the operating room, further advancements are needed to fully realize its capabilities. Addressing challenges associated with direct contact with biological fluids, such as biofouling and electrode passivation, will be essential for optimizing the device for in situ chemical analysis. The utilization without the need for sample preparation can fully exploit its potential.

All in all, Lab-on-a-Scalpel connects analytical chemistry and biomedical engineering by combining an electroanalytical sensor with a medical tool to construct an advanced multifunctional device. This device can promote point-of-care diagnostics in surgical theaters and holds promise to become an essential tool for robotic-assisted surgery. Its integration in such robotic platforms can improve the accuracy of the procedure by adjusting its actions in response to the biochemical profile of the patient. (44) In this manner, this can improve the efficiency of the procedure and ensure patient safety. Upon connection with wireless data transmission technologies, Lab-on-a-Scalpel can communicate with other surgical instruments and monitoring systems that will pave the way for its broader adoption in next-generation, smart surgical environments.