News from LabRulezLCMS Library - Week 23, 2025

LabRulez: News from LabRulezLCMS Library - Week 23, 2025

Our Library never stops expanding. What are the most recent contributions to LabRulezLCMS Library in the week of 2nd June 2025? Check out new documents from the field of liquid phase, especially HPLC and LC/MS techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT LCMS AND RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezGCMS or LabRulezICPMS libraries.

This week we bring you application notes by Agilent Technologies, Knauer, Shimadzu, Thermo Fisher Scientific and Waters Corporation!

1. Agilent Technologies: Analysis of PFAS Compounds on the Agilent InfinityLab Pro iQ Plus Mass Detector

- Application note

- Full PDF for download

Per- and polyfluoroalkyl substances (PFAS) are a group of persistent and harmful chemicals that can be commonly found in the environment globally.1 Applications such as evaluating PFAS removal through novel treatment technologies, tracking remediation efforts, and identifying emerging contaminants often rely on advanced analytical tools. While triple quadrupole mass spectrometers deliver the sensitivity and specificity required for most PFAS applications, they come with higher maintenance costs and often require a larger laboratory footprint.

The compact and cost-efficient Agilent InfinityLab Pro iQ Plus single quadrupole LC/MS system offers a streamlined alternative for applications where compliance with regulated methods is not required and/or when expected concentrations exceed sub-ppb levels. This could be the case for research facilities looking into emerging technologies for the investigation of remediation strategies, or for production facilities, such as electronics and semiconductor manufacturing sites, monitoring PFAS emissions. Furthermore, this system can be implemented in laboratories with limited infrastructure for mass spectrometry, providing a fully integrated solution for data acquisition and analysis with Agilent OpenLab CDS.

This application note describes the performance of the InfinityLab Pro iQ Plus for PFAS analysis using standards in solution with replicate injections.

Experimental

Instrument configuration

This experiment was conducted using the following instrument configuration:

- Agilent Pro iQ Plus LC/MS system (G6170A)

- Agilent 1290 Infinity II bio binary pump (G7120A)

- Agilent 1290 Infinity II bio multisampler (G7167B)

- Agilent 1290 Infinity II bio column compartment (G7116B)

LC/MS analysis

The samples were analyzed using C18 reversed‑phase chromatography (Agilent ZORBAX RRHD Eclipse Plus C18 column, part number 959758-302) with a UHPLC guard column (Agilent ZORBAX RRHD Eclipse Plus C18 guard column, part number 821725-901) on an Agilent 1290 Infinity II LC. The LC was equipped with a delay column (Agilent InfinityLab PFC delay column, part number 5062-8100) and the Agilent InfinityLab Pro iQ Plus single quadrupole mass spectrometer, along with an Agilent Jet Stream (AJS) source. To provide better quantification, data were simultaneously collected in negative scan mode with corresponding selected ion monitoring (SIM) for each analyte. Data were acquired and analyzed using OpenLab CDS 2.8. Source parameters, SIM parameters, and HPLC parameters are shown in Tables 2, 3, and 4, respectively.

Results and discussion

Good chromatographic separation using the reversed-phase C18 column is achieved over the 14.5-minute gradient (Figure 1). The calibration curves show good linearity with precision between 82% and 114% and area relative standard deviation (RSD) less than 10% at limit of quantification (LOQ, Table 5). The LOQs range from 0.1 to 0.5 ng/mL for all analytes, with most values at 0.2 ng/mL or lower. Data processing method development was facilitated by the Integration Optimizer Wizard within the OpenLab Data Analysis (DA) module. This software provides users with a step-by-step workflow to optimize individual detection and integration settings for the various analytes (Figure 2).

Conclusion

The method described in this application note offers a practical approach to sub-ppb PFAS quantification using SIM acquisition with an integrated solution for data analysis. The Agilent InfinityLab Pro iQ Plus LC/MS system demonstrates excellent sensitivity, as well as a good linearity and reproducibility, for a unit mass detector. The integrated workflow from data acquisition to final reporting with Agilent OpenLab CDS 2.8 provides users with a smooth delivery of analytical results.

2. Knauer: Systematic and efficient method scale-up for peptide purification

- Application note

- Full PDF for download

Peptides, composed of short chains of amino acids, bridge the gap between small organic molecules and large proteins. They offer advantages such as specificity, selectivity, and lower immunogenicity. Recent approvals of peptide-based drugs highlight their growing significance in therapeutic areas like metabolic disease, cardiovascular health, and oncology [1].

Peptide synthesis involves creating peptide bonds between amino acids to form peptides. Solid-phase and liquid-phase methods are commonly employed, with solid-phase synthesis, introduced by Merrifield, being prominent. This process has been refined through innovations in automation and chemistry [2]. High-performance liquid chromatography (HPLC) serves both analytical and purification purposes in peptide synthesis [3]. It is applied in tracking reaction progress, verifying intermediate identities, and confirming the purity of the final peptide [3]. Here, we show a HPLC method development and method scale-up for peptide purification.

MATERIAL AND METHODS

Column

- Eurospher II 100-5 C18 (150 x 4 mm): For all analytical measurements

- Eurospher II 100-10 C18 (150 x 4 mm): For particle scale-up experiments

RESULTS

The crude peptide was measured using an analytical HPLC system (see Fig. 1). A method with an overview gradient from 10 to 100 % organic eluent was applied.

One large peak was identified as Angiotensin I. Several neighboring impurities were observed. The purity of the crude Angiotensin I was confirmed to be about 68.05 % (target peak area relative to impurities peak areas).

As a first step for scale-up of an analytical method, the particle size was increased from 5 to 10 µm (see Fig. 2), to mitigate the increase in backpressure at higher flow rates in preparative scale.

A focused gradient was applied to increase resolution of Angiotensin I and the neighboring impurities (see Fig. 3). The method was shortened, introducing a wash step with 100 % organic eluent into the gradient, followed by an equilibration step to starting conditions. This removed all late eluting impurities and shortened the overall method runtime.

With an optimized method a volume overload study was performed to gather insight of the target peaks elution behavior (see Fig. 4). It was observed that above 50 µl injection volume, separation of impurities and target substance was poor. Therefore 50 µl was taken as calculation base for scale-up. Since all experiments were in analytical scale, sample loss could be kept minimal. The next step in the linear scale-up workflow was the increase of the column inner diameter (ID) from 4 to 20 mm. Using the KNAUER HPLC Method Converter, preparative scale method parameters were calculated (see Fig. 5) (https://www.knauer.net/ lc-method-converter).

Finally, the method was transferred into preparative scale and to a preparative HPLC system. 2000 µl of crude sample with a concentration of 1 mg/ml were injected. The target peak eluted as predicted and was fractionated with the first run already. Fraction slices of 2.5 ml were chosen. The target fractions were pooled and analyzed using the original analytical HPLC method confirming a purity of >99 % (see Fig. 6). That results in 1.4 mg of purified peptide per run.

CONCLUSION

In conclusion, the linear scale-up of the analytical HPLC method for purifying crude Angiotensin I proved effective in enhancing the purity of the target peptide. By systematically increasing the particle size and adjusting method parameters, such as the gradient and injection volume, the method was optimized for preparative scale. The successful transfer to a preparative HPLC system, guided by linear scale-up principles, enabled efficient fractionation of the target peptide with high purity (>99 %) achieved in the pooled fractions. This underscores the importance of linear scale-up in maintaining method robustness and ensuring the successful purification of peptides at a larger scale

3. Shimadzu: Analysis of Per- and Polyfluoroalkyl Substances (PFAS) Using Triple Quadrupole Mass Spectrometer Part 2 -Milk-

- Application note

- Full PDF for download

User Benefits

- The optimized procedure for pretreatment and LC-MS/MS analytical conditions enable accurate quantification of thirty major PFASs targeted by AOAC SMPR from 0.01 µg/kg in milk.

- The method allows the initiation of PFASs analysis in food.

Per- and Polyfluoroalkyl Substances (PFASs) are a collective name for more than four thousand organofluorine compounds. Perfluorooctane sulfonic acid (PFOS) and perfluorooctanoic acid (PFOA) are representative compounds of PFAS. They are used in a wide range of applications, such as fire retardants, food packaging materials, and non-stick coatings, due to their waterrepellent, oil-repellent, heat-resistant, and chemical-resistant properties. Due to their structural stability, PFAS widely remains in the environment.

Recent studies have revealed that PFAS can transfer into dairy products when dairy cows ingest feed or water contaminated with PFAS1). There are concerns about the potential health risks caused by human ingestion of PFAS-contaminated dairy products. Therefore, quantitative assessment of PFAS levels in dairy products should be important. To monitor PFAS concentrations in dairy products, a highly accurate and sensitive quantification method is essential.

This application news introduces a quantitative analysis of PFAS in dairy milk with LC-MS/MS. Thirty PFASs targeted by AOAC INTERNATIONAL2) were analyzed and evaluated by spike recovery test. By optimizing the analytical conditions, good recoveries were obtained for all compounds.

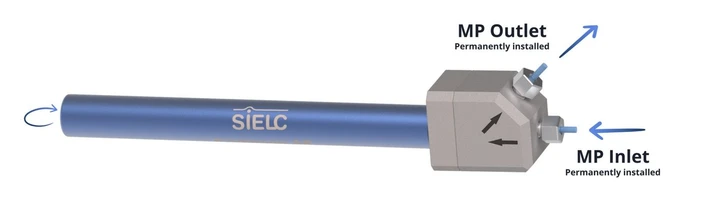

Analytical conditions

Analysis was performed using a triple quadrupole mass spectrometer LCMS-8060NX equipped with an ultra-high performance liquid chromatograph NexeraTM X3 UHPLC (Fig. 1). The analytical conditions are shown in Table 1. To prevent interference caused by PFAS contamination from solvents, a delay column was installed between mixer and autosampler using SUS piping (300 mm x 0.3 mm I.D., P/N: 228-69955-41). The delay column increased the elution time of PFAS derived from solvents, allowing it to be separated from the PFAS in the sample. PP vials (Shimadzu GLC, P/N: GLC-IVS-100) confirmed to have no detectable PFAS were observed.

Conclusion

This application news describes the analysis of thirty PFAS targeted by AOAC INTERNATIONAL in dairy milk samples. The analysis was performed using LCMS-8060NX coupled with a Nexera X3 UHPLC system. A Shim-pack Scepter column was employed to achieve good separation and peak shape. Recovery tests demonstrated satisfactory results, with recovery rates within 92.0-119.6% and repeatability below 15.7% for all compounds at spiking concentrations of 0.01, 0.1, and 1 µg/kg. Notably, PFOA, PFNA, PFHxS, and PFOS showed recovery rates within 95.7-112.5% at all spiking concentrations.

4. Thermo Fisher Scientific: Screening of per- and polyfluoroalkyl substances (PFAS) in food contact materials: Utilizing a new combustion-ion chromatography system for total organic fluorine (TOF) analysis

- Application note

- Full PDF for download

Per- and polyfluoroalkyl substances (PFAS) have been intentionally added to food contact materials (FCM) for decades to confer grease and water repellency. PFAS are highly persistent, bioaccumulative, and toxic. Consequently, the use of PFAS in FCM presents significant concerns related to direct human exposure and environmental pollution at the end of their lifecycle.

In response to these concerns, twelve states in the United States have or will legislate the use of PFAS in food packaging due to the absence of federal action. For example, California has banned all plant fiber-based food packaging containing PFAS that are either intentionally added or present at levels exceeding 100 parts-per-million (ppm) total organic fluorine (TOF), effective January 1, 2023.

In Thermo Scientific Application Note AN003644, we developed a method to measure TOF in FCM using combustion-ion chromatography (C-IC).1 This application proof note demonstrates the determination of TOF in FCM using an enhanced C-IC system. The Thermo Scientific™ Cindion™ C-IC System combines the Thermo Scientific™ Dionex™ Inuvion™ IC System, featuring reagent-free ion chromatography (RFIC™), with the Thermo Scientific™ Cindion™ Combustion/Absorption Module. The system is optimized for increased combustion efficiency by incorporating a z-fold combustion tube to introduce oxygen at multiple points. As a result, the combustion tube and furnace are shorter, and combustion times are reduced. This also results in a smaller footprint, saving valuable bench space. Additionally, the C-IC system is controlled by a single software, the Thermo Scientific™ Chromeleon™ Chromatography Data System (CDS), enhancing data processing and system management efficiency.

Conclusion

The TOF results for the three samples (S1–S3) from AN003644 were closely aligned with the previous findings, with values that were 98% to 101% of those found in the application note. In AN003644, TIF was measured by directly injecting samples through four external injection channels, which required manual sample changes after every four analyses and large sample volumes. In contrast, the new C-IC system offers a versatile 2-in-1 configuration, allowing seamless switching between C-IC and standalone IC with the Dionex AS-AP autosampler. This configuration significantly improves efficiency and convenience. The TOF method provides a valuable tool for manufacturers to comply with current state regulations on PFAS in food contact materials.

5. Waters Corporation: Application of LC-UV/MS Workflows to Increase Efficiency in Impurity Profiling of GLP-1 Analogs

- Application note

- Full PDF for download

Benefits

- Orthogonal mass information provides data-driven insights on forced degradation impurities generated via oxidation, pH, and thermal stress.

- The ACQUITY QDaTM II Mass Detector enhances the capabilities of analytical labs in raw material screening, process control, lot release, and stability monitoring.

- LC-UV/MS workflow expedites risk-based decision-making and increases overall productivity in the lab

Glucagon-like-peptide-1 receptor agonists (GLP-1 RAs) have been widely used as medications to treat type 2 diabetes and obesity. While relatively simple in structure as a short chain of amino acids, the production and modification of GLP-1 analogs can be quite varied (Figure 1A). Briefly, the peptide backbone can be produced via recombinant DNA techniques or chemical synthesis (in solid phase, liquid phase, or a hybrid of both). Modifications, if present, are made via chemical conjugation to add a fatty acid chain or protein fragment to prolong half-life or achieve other desired pharmacokinetic and/or pharmacodynamic effects.1

As GLP-1 analogs become increasingly complex, particularly with conjugates, new challenges arise in identifying and defining acceptance criteria in their production. To meet product demand while maintaining regulatory expectations for safety and quality, manufacturers need reliable and easy methods that can be logistically deployed to support the production of GLP-1 analogs.

LC-UV/MS platforms offer the potential to alleviate the workload on analytical laboratories during method development and manufacturing activity while maintaining drug quality and safety. Access to orthogonal mass information allows support labs to make informed decisions more efficiently during method development and manufacturing to reduce errors and increase overall productivity. This study aims to demonstrate the inherent value of mass information in workflows related to raw material screening, process control, lot release, and stability monitoring to expedite decision-making and increase overall lab productivity. This will be accomplished through a data-driven discussion with use cases presented for GLP-1 analogs that undergo forced degradation conditions including oxidation, pH, and thermal stress.

Results and Discussion

Stability Testing

As part of development and manufacturing, drug substances undergo forced degradation using thermal, chemical, and UV-stress to determine stability, shelf-life, and storage conditions. In this setting, LC-UV/MS workflows can be utilized to quickly identify degradants and potential stability indicating attributes for routine monitoring. As an example, exenatide was placed under thermal stress for a 30-day period and analyzed using an LC-UV/MS workflow. As shown in Figure 2A, several new peaks were observed in the UV chromatogram of the thermally stressed sample with 7 peaks exhibiting a significantly elevated peak area. As shown in the bottom panel, the ACQUITY QDa II Mass Detector is readily capable of detecting all observed peaks enabling the use of orthogonal mass data to putatively identify degradants. An example is shown for peak 2 in which a related ion series ([M+3H]+3 and [M+4H]+4) was observed in the spectral data and determined to correlate to a mass of 3,254.1 Da. Using this information, a quick examination of the amino acid sequence indicated this mass potentially represents a single cleavage occurring between the aspartic acid and leucine residues of exenatide (Figure 2B). Extracted ion chromatograms (XICs) were performed on full spectrum data of the thermally stressed sample. As shown in Figure 2B, a matching set of peaks were identified for the [M+4H]+4 and [M+2H]+2 charge states related to the peptide fragments, potentially indicating a site of thermal instability that may need further development in terms of sequence and activity.

Conclusion

In this study, it was demonstrated how the ACQUITY QDa II Mass Detector can be effectively utilized to support impurity profiling and stability testing activity associated in the production of GLP-1 analogs with the following observations:

- Compact mass detectors such as the ACQUITY QDa II Mass Detector that feature on/off simplicity and can be easily integrated into existing LC-UV platforms have the potential to lower adoption barriers associated with MS and increase the analytical capabilities of supporting labs.

- Access to mass data provides deeper understanding of drug product behaviors enabling more insightful decision-making during the development and manufacturing process

- In-line acquisition of complementary orthogonal mass data increases confidence in results and product knowledge for improved product safety and regulatory compliance while maintaining productivity