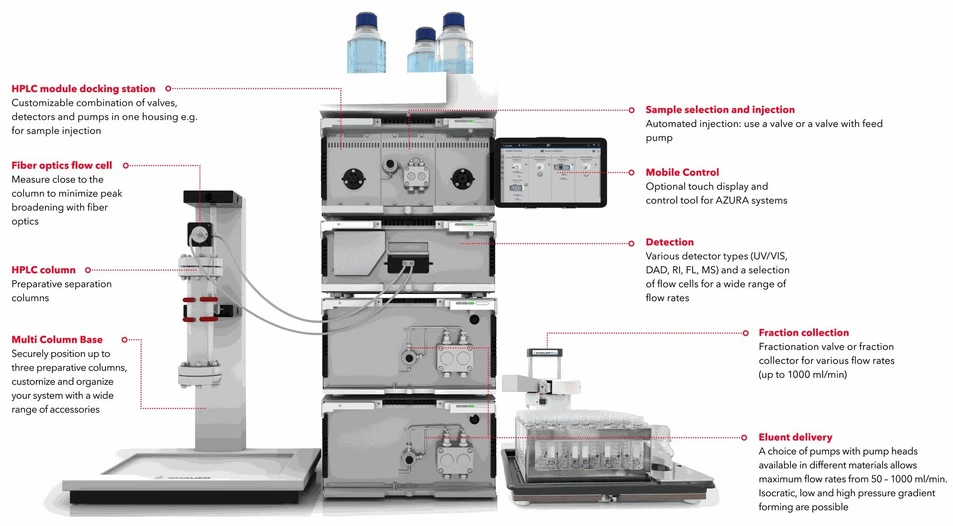

KNAUER AZURA® Pilot Prep HPLC System

AZURA® Preparative HPLC Customized purification

AZURA® preparative systems are the perfect solution for frequently changing separation tasks – from milligram to kilogram scale. Design your AZURA preparative system to your needs and combine flexibility and reliability.

Customaze your system

AZURA® Prep systems are tailor-made for you. Configure your system from injection to detection and choose between different materials, flow rates, valves, and detectors.

Easy scale up from compact to pilot systems

Due to the flexible design of our devices, you can easily change parts like pump heads or flow cells and integrate all components of the compact into the pilot-scale system.

Stacked injections, peak & solvent recycling

AZURA® Prep systems can be used for special separation modes like peak recycling and stacked injections. We help you to configure your system and choose the best software for you.

Flexibility and performance

KNAUER AZURA® Prep HPLC System.

KNAUER AZURA® Prep HPLC System.

AZURA® Pilot Prep HPLC System

Choose the Pilot Prep LC system if you want to increase your productivity even more. As for the AZURA Lab Prep LC system you can freely build up your system. Flow rates up to 1 000 ml/min and loads up to several grams are possible. Optional peak and solvent recycling can be set up to increase separation power and reduce separation costs significantly

KNAUER: AZURA® Pilot Prep HPLC System.

KNAUER: AZURA® Pilot Prep HPLC System.

- Pilot Prep HPLC system with binary high-pressure gradient

- Binary or ternary HPG/LPG, isocratic flow modes

- Flow rates up to 1000 ml/min

- 20-150 mm recommended column ID

- Injection system: Sample pump with injection valve for automated handling of large sample volumes

- Detection system: Supports UVD (VWD, MWD, DAD), RID, FLD, ELSD, MS with split-free UV detection and various flow cell designs

- Fraction collection: 12-port fractionation valve for automated collection of small and large fractions

- Stacked injection for high-throughput

- Software: Intuitive PurityChrom® for direct control and visualization

- Regulatory compliance: GMP (21 CFR part 11) compliant software and certificates for wetted parts

- Efficiency features: Solvent recycling to reduce costs and environmental impact, peak-recycling for high resolution

- High-throughput applications: Liquid handler enables purification of peptides and oligonucleotides

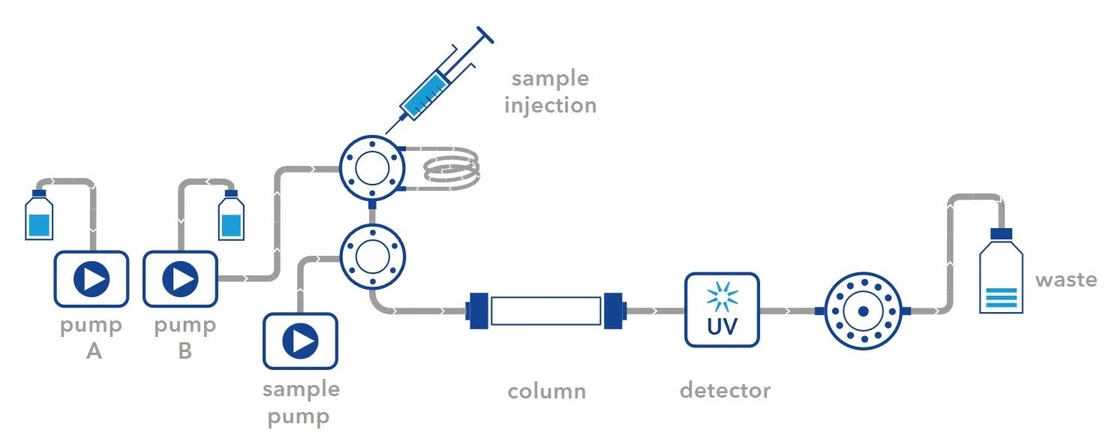

Improved purity by combining online SPE with preparative LC

Steviol glycosides are the main sweetening compounds in Stevia rebaudiana and are often used as natural sugar substitutes. To enable commercial usage, the plant extracts need to be purified. In this work, preparative online SPE (solid phase extraction) with the AZURA Pilot Prep LC was investigated for improving overall purity by reducing matrix contamination.

The steviol glycoside rebaudioside A is the main compound of interest as it is the sweetest and least bitter compound of the extract. Often, Stevia products contain a mixture of rebaudioside A and stevioside. Developing a purification method with a high yield of rebaudioside A, minimal stevioside impurities, and high throughput increases the economic output of Stevia production.

KNAUER: AZURA® Pilot Prep HPLC System.

KNAUER: AZURA® Pilot Prep HPLC System.

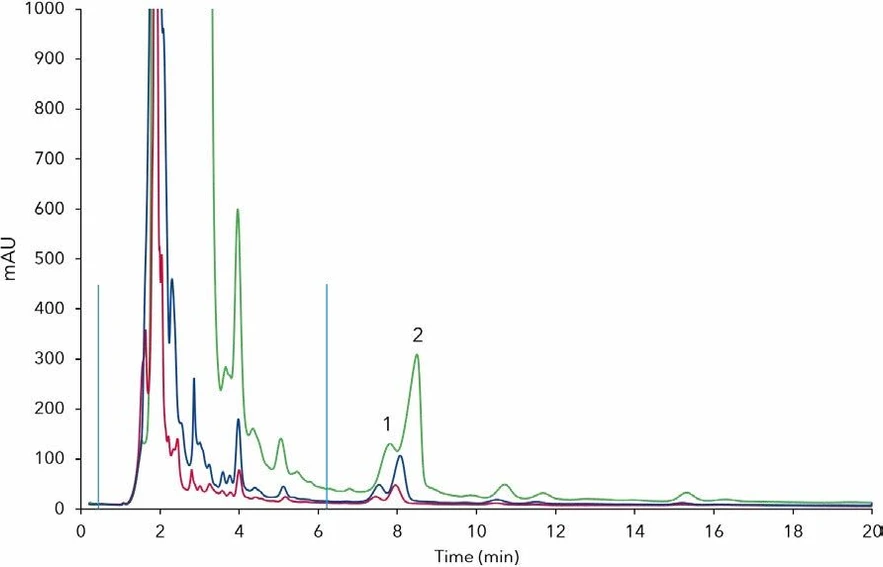

Results

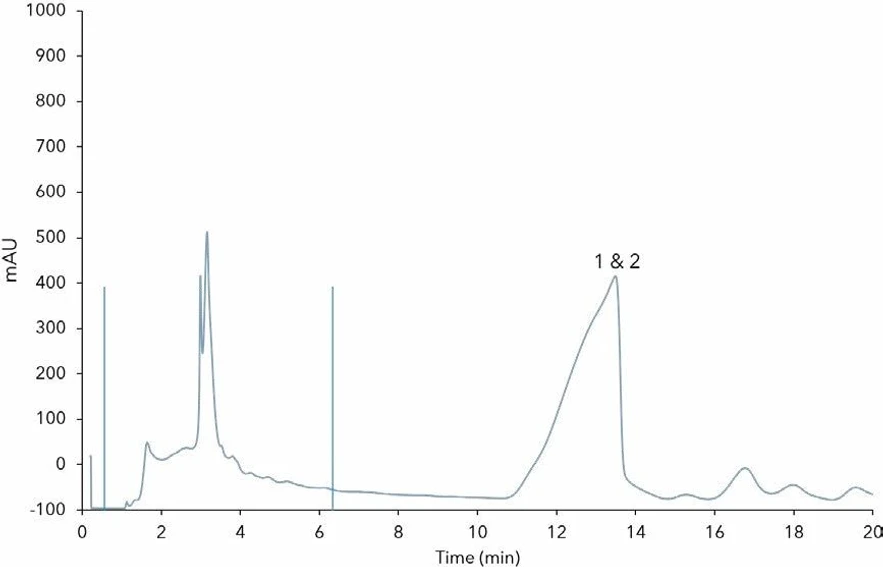

Fig. 1 shows the batch LC without online SPE. The matrix peak (1-5 min) negatively affects the separation abilities.

KNAUER: AZURA® Pilot Prep HPLC System : Overload experiments on preparative column, 200 μL (red), 500 μL (blue), 2000μL (green); 1) rebaudioside A, 2) stevioside, blue bars – matrix, 25°C, 22 ml/min.

KNAUER: AZURA® Pilot Prep HPLC System : Overload experiments on preparative column, 200 μL (red), 500 μL (blue), 2000μL (green); 1) rebaudioside A, 2) stevioside, blue bars – matrix, 25°C, 22 ml/min.

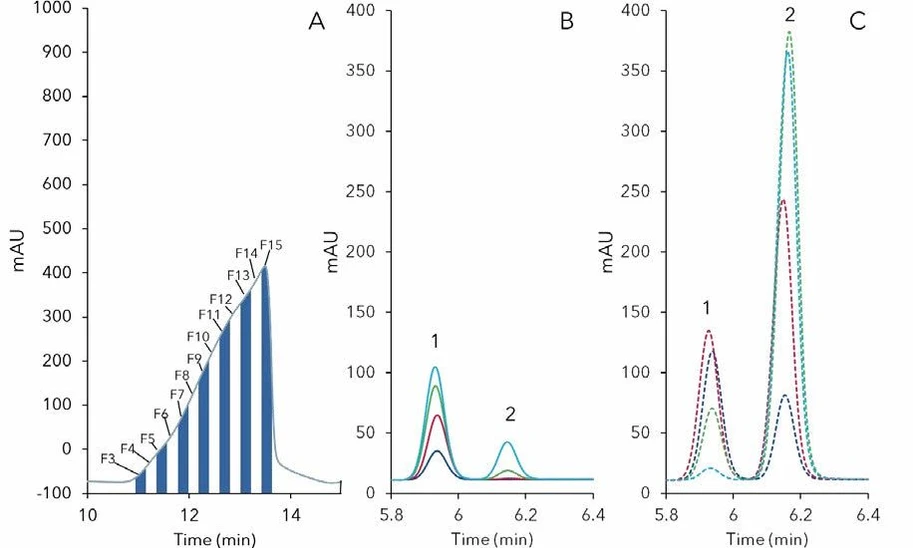

In comparison, Fig. 2 shows that the automated SPE process significantly decreased the matrix. The fraction analysis revealed that only a small part of the overlapping peak contained nearly pure rebaudioside A; fractions 3-5, approximately 15 mL, had >90% rebaudioside A and <10% stevioside (Fig. 3B).

KNAUER: AZURA® Pilot Prep HPLC System: Preparative online SPE, 10 mL loading; 1) rebaudioside A, 2) stevioside, blue bars – matrix, 25°C, 22 mL/min.

KNAUER: AZURA® Pilot Prep HPLC System: Preparative online SPE, 10 mL loading; 1) rebaudioside A, 2) stevioside, blue bars – matrix, 25°C, 22 mL/min.

The later fractions contained high amounts of stevioside but also still rebaudioside A (Fig. 3C). The results showed that purification of highly pure rebaudioside A is possible with an additional online SPE.

KNAUER: AZURA® Pilot Prep HPLC System: Fraction analysis of preparative online-SPE purification (Fig.2) of rebaudioside A (1) and stevioside (2); a) F3 (blue), F4 (red), F5 (green), F6 (light blue); b) F7 (red dashed), F10 (blue dashed), F12 (green sashed), F15 (light blue dashed); c) frac- tionation of target peak, 5 mL fractions.

KNAUER: AZURA® Pilot Prep HPLC System: Fraction analysis of preparative online-SPE purification (Fig.2) of rebaudioside A (1) and stevioside (2); a) F3 (blue), F4 (red), F5 (green), F6 (light blue); b) F7 (red dashed), F10 (blue dashed), F12 (green sashed), F15 (light blue dashed); c) frac- tionation of target peak, 5 mL fractions.